UW-Madison Formula Electric Battery

Projects

Battery Chassis

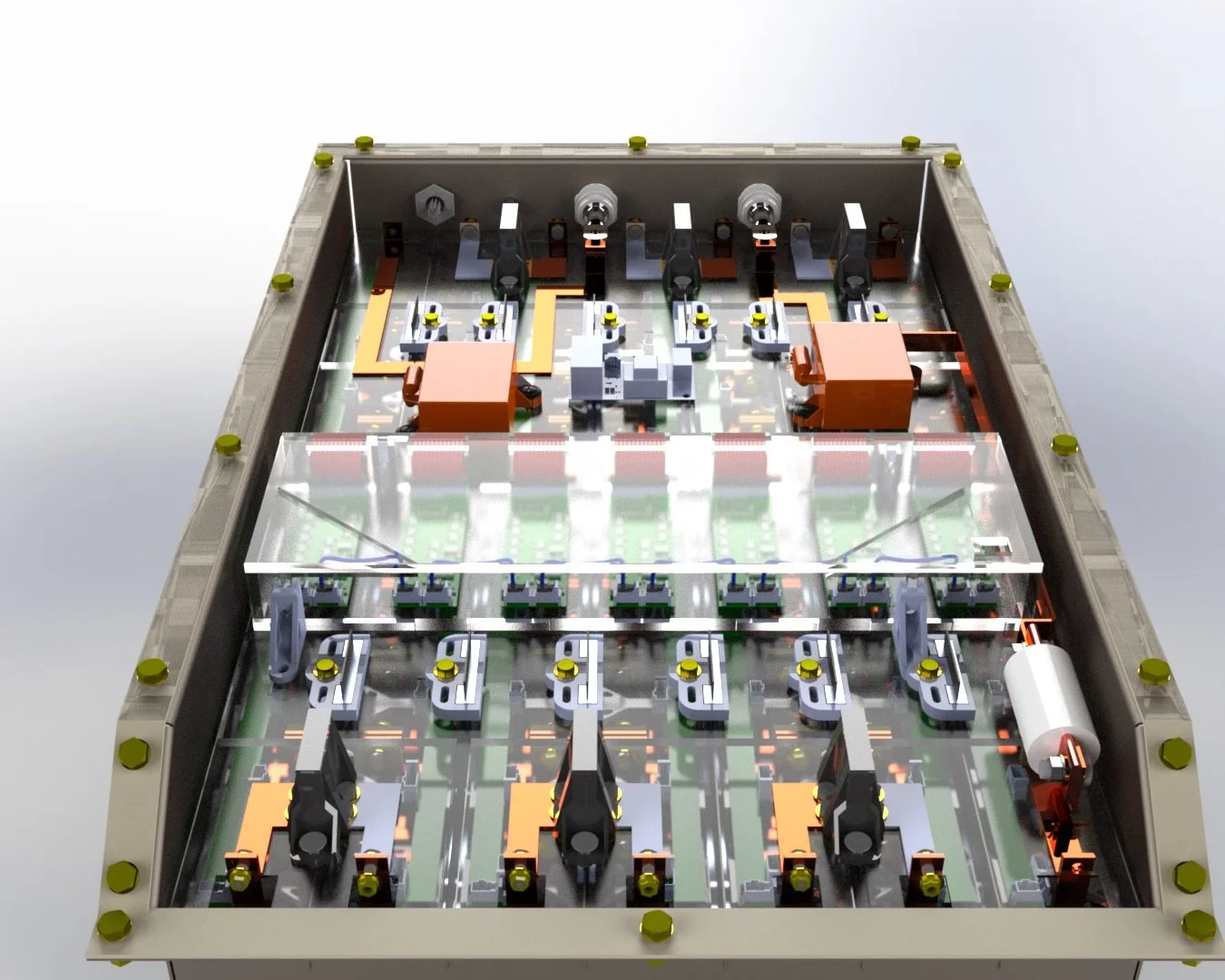

Battery Power Routing & Layout

Inverter Housing

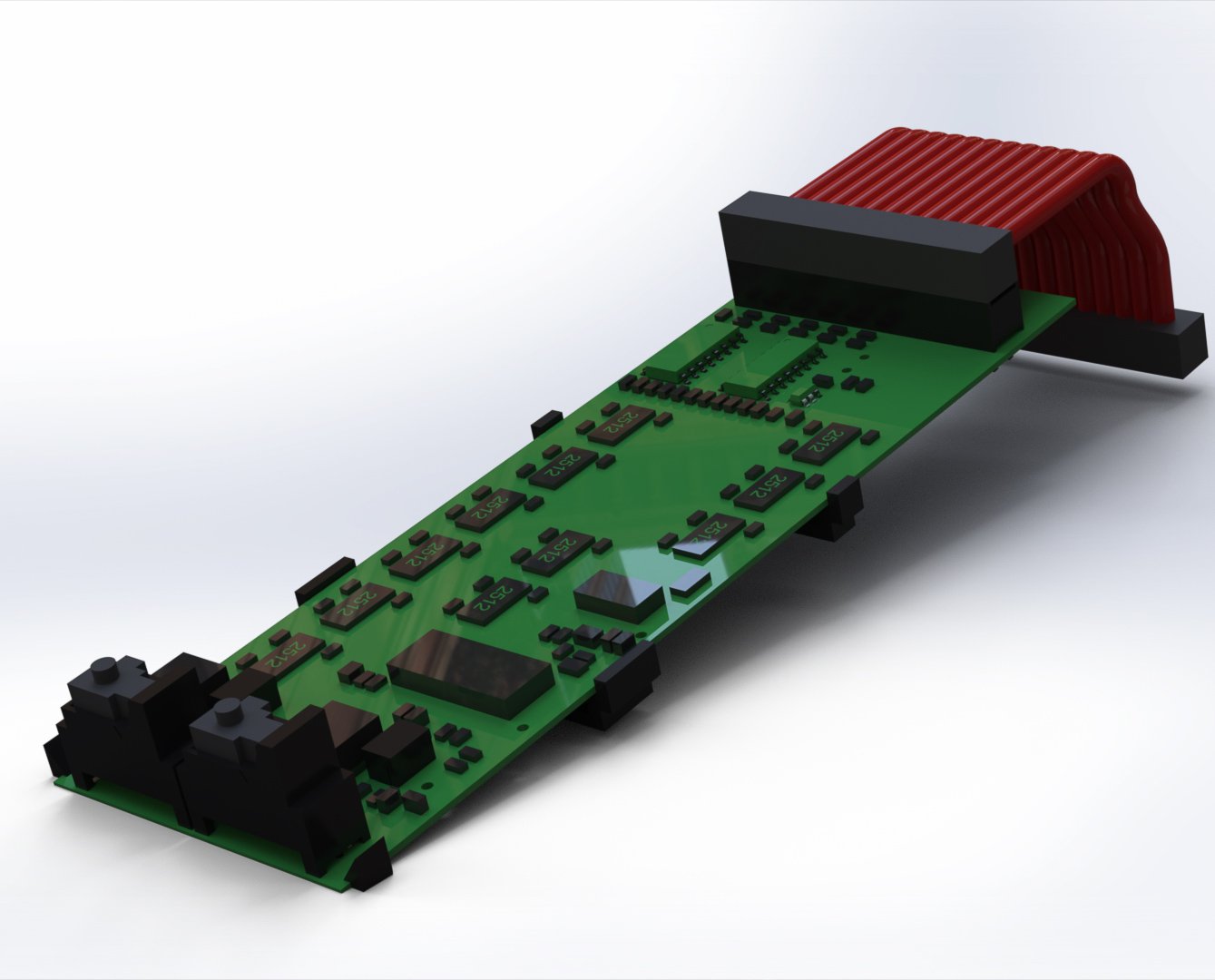

BMS Housing

Vehicle CAD and Rendering

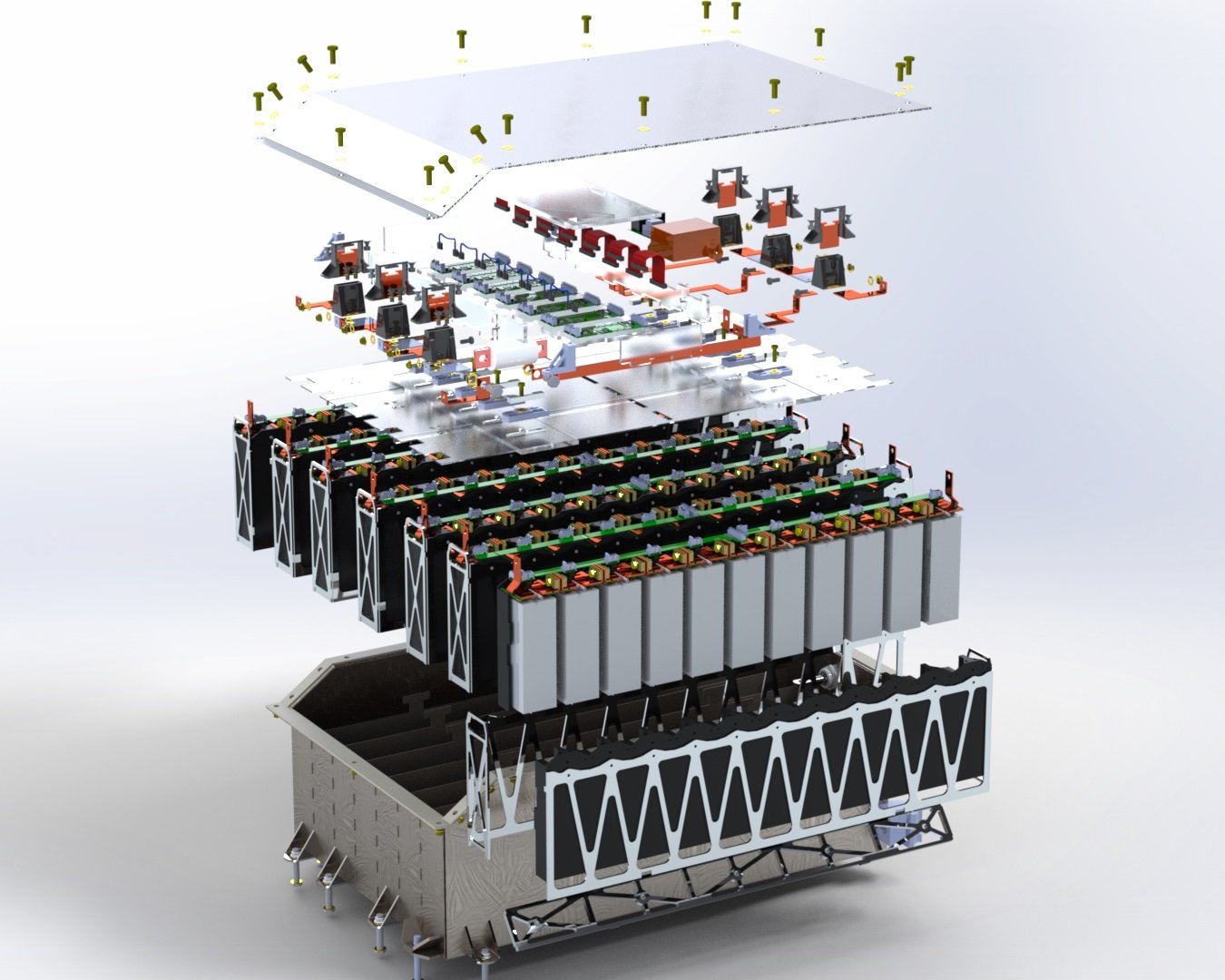

Overview

While I was a member of UW-Madison’s Formula SAE Electric team at UW-Madison I worked on the development, design, and manufacturing of the high voltage voltage battery for the E-Car for my mechanical engineering undergraduate capstone project. We designed the battery from ground up to replace the 2019 electric battery. The battery operated at 320 volts and had an energy storage capacity of 7.5 kWh to supply a continuous 60 kW to the four independent motors. We used 308 Malesta Lithium-ion pouch cells to meet the run time, power targets, and form factor requirements. I was responsible for the mechanical design of the battery including the cell selection, cell layout, system design, chassis design, power routing design, and frame design. Development of the battery also allowed me to work closely with our electrical engineers to help with the layout of our battery segment PCBA’s, battery BMS board, and inverter boards.

Processes Utilized

3D Modeling & Rendering (Solidworks)

Sheet Metal Stamping & Bending

Composites Manufacturing

Powder coating & Plating

3D printing (FDM & SLA)

PCBA Design

Waterjet

Laser Cutter

CNC Router

CNC Machining

Tig Welding

Resistance Welding

Laser Welding

Wire EDM

Top Skills Utilized

CAD modeling

Engineering Drawings

Mechanical Design

Design for Assembly

Battery Design

CNC Machining

Material Coating

Welding

FEA Simulations

Battery Chassis Development

Battery Power Routing & Layout

Inverter and BMS Housing

CAD & Renders